Contribute to the advancement of technology in the metallurgy sector.

Contributing to the search for new machining techniques, AAMS has conducted several studies demonstrating the effectiveness of the methods used:

Case study 1

Context :

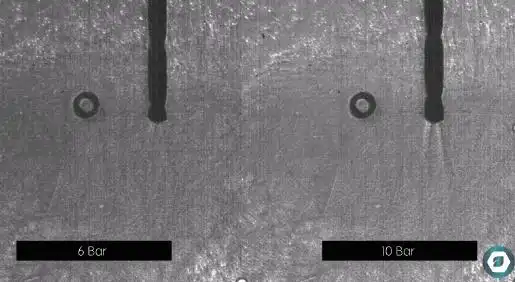

Deep hole drilling = high pressure pumps usage – automotive sector.

Objective :

Convert to MQL drilling – energy saving.

Methods :

1- Select optimum tools on market

2- Define MQL parameter (oil variant + up to 10 bars)

3- Proof of concept

4- Tool life test

Conclusions :

MQL suitable

Energy saved

ISO tool life MQL VS Wet

Case study 2

Context :

Consortium project – end user, oil provider – aerospace materials.

Objective :

Evaluation of tool life using 5 wet variants.

Methods :

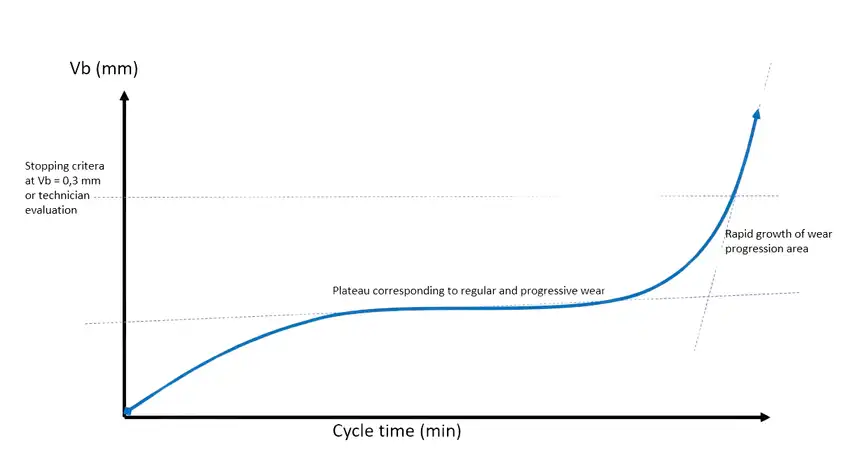

1- Tool life testing protocol definition

2- Oil benchmark tool life test (3 repeats)

3- Tool wear analysis

Conclusions :

Up to 30% tool life difference

Tool costs decrease

Case study 3

Context :

End user anticipating production growth in medical sector.

Objective :

Audit of production unit and improve productivity.

Methods :

1- One day audit of production unit and actions plan

2- Test performed on production site

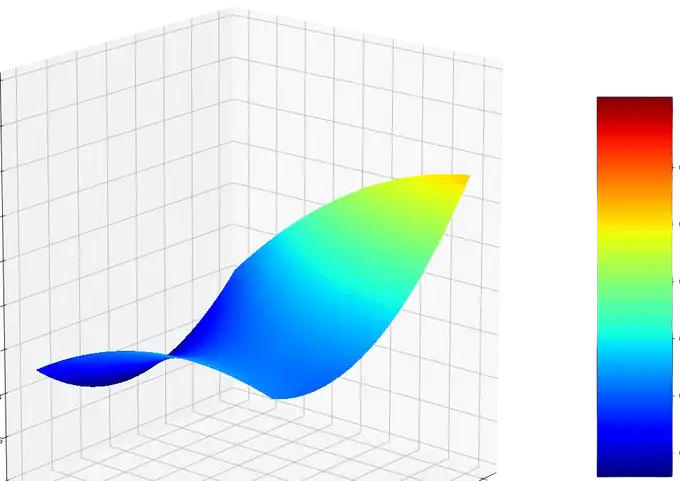

3- Delivery of machinability maps using DOE technics

4- Production parameters change + follow-up

Conclusions :

Up to 40% productivity gain.

Case study 4

Context :

Consortium projet (Tool manufacturer, University, AAMS).

Objective :

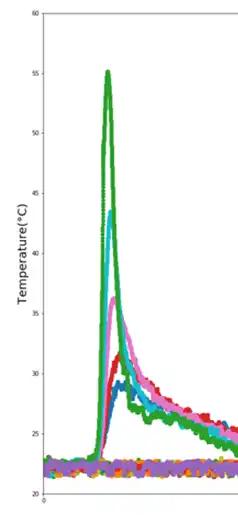

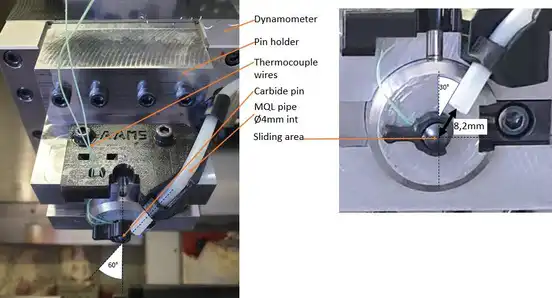

Evaluate friction coefficient and thermal contribution of an AlTiSiN coating in order to find cutting solution for Gamma-TiAl alloys.

Methods :

1- Testing strategy using DOE

2- Usage of a high speed and high pressure pin and cylinder set-up

3- Testing of Ti-6Al-4V alloy versus Gamma TiAl in dry/wet and MQL lubrication condition

4- Measurement of sliding forces and heat flux through pin

Conclusions :

Creation of coating friction map knowledge package for consortium.

Case study 6

Context :

consortium project (end user, material and tools provider– aerospace market).

Objective :

Mechanical test specimen manufacturing.

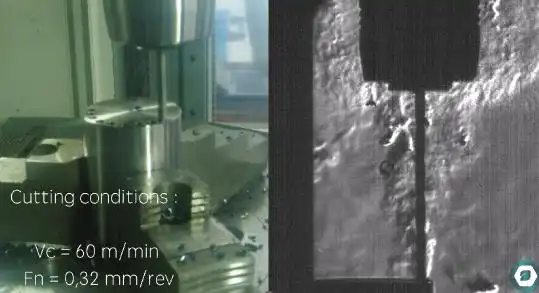

Methods :

1- Manufacturing process creation

2- Specimen manufacturing

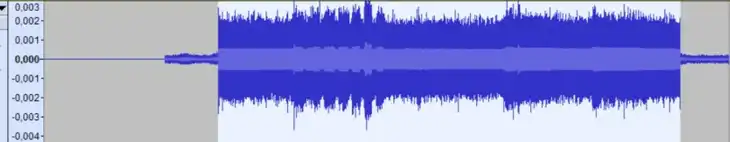

3- During manufacturing recording of :

• Specimen T°C and heat flux load history

• Specimen mechanical load history

• Specimen vibrations load history

• Specimen roughness 3D map

Conclusions :

Qualification of new machining process.